Furnace Frame

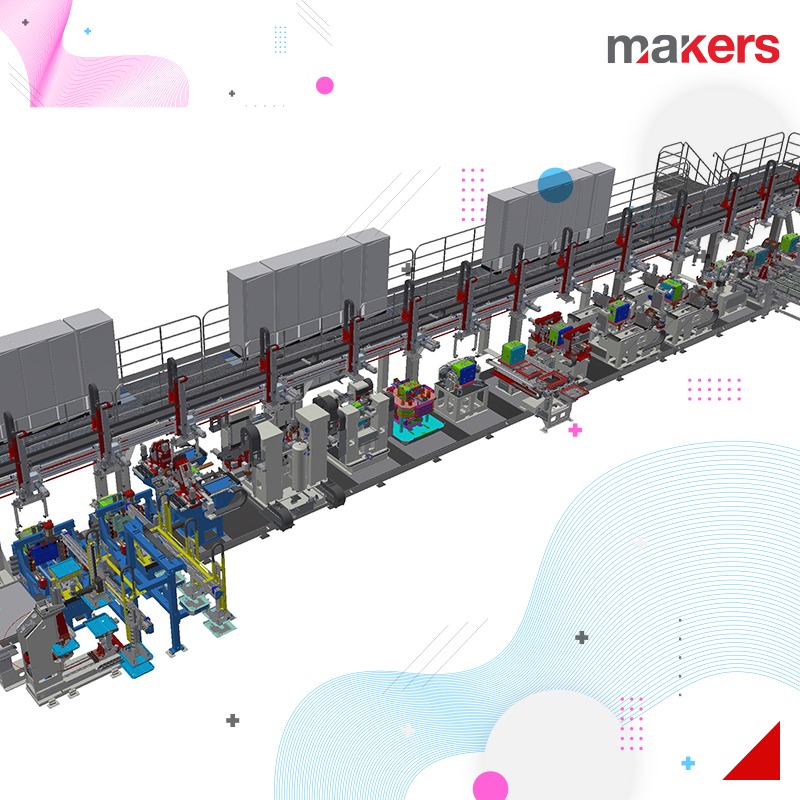

Welding and Transfer Line

A production line consisting of 16 different machines, 20 Cartesian, 3 hydraulic presses, more than 15,000 I/O, 7 robots, 88 servo motors, 3,500 pages of electrical projects and countless electrical components. All of the drives used in white goods factory automation are available on this line. Servo control, hydraulic, pneumatic and mechanical drives (springs) are all used by Makers' experienced team in this line in accordance with current technology and motion calculations.

This line transforms the inner frame of household furnaces with joining, forming and bending methods.

By using MFDC technology, which is the new trend in electric resistance welding applications, which Makers is ambitious about, it handles welding time, quality and cost in the most accurate way.

There are stations at many different points of the production line that offer image processing and multiple measurement options. At the exit of the presses, the process is controlled by image processing so that the product can feed the line correctly. The quality of Makers is hidden in the precision of the products that are subjected to different processes in the machines or automation lines.

The Furnace Chassis Welding and Transfer line produces 1 chassis in 15 seconds by applying more than 27 processes to stainless steel. This production line can produce chassis not only for one chassis model but also for more than one model. This process does not require any extra tools and equipment other than the replacement of the part feeding the line.

This line, produced by Innovative Engineering, is equipped with high level security measures despite its short cycle time. The 16 doors that can enter the line are equipped with the most secure systems.

Although this line is a compact automation line, it is possible to access servo controls, hydraulic controls, pneumatic controls, instantaneous values of the cooling water used in the welding heads, all safety situations, robot controls and instantaneous measurement values from 8 different HMI panels positioned on the line. Even the information of the minimum air lost by the system can be accessed from these panels.

The "Etna2" welded production line, designed, manufactured and commissioned by Makers with an innovative engineering approach, is a compact production line that incorporates all current factory automation technologies and complies with all quality standards.