Glass Industry

As an Innovative Engineering, we produce transfer and high precision drilling lines for the glass industry with different robotic methods.

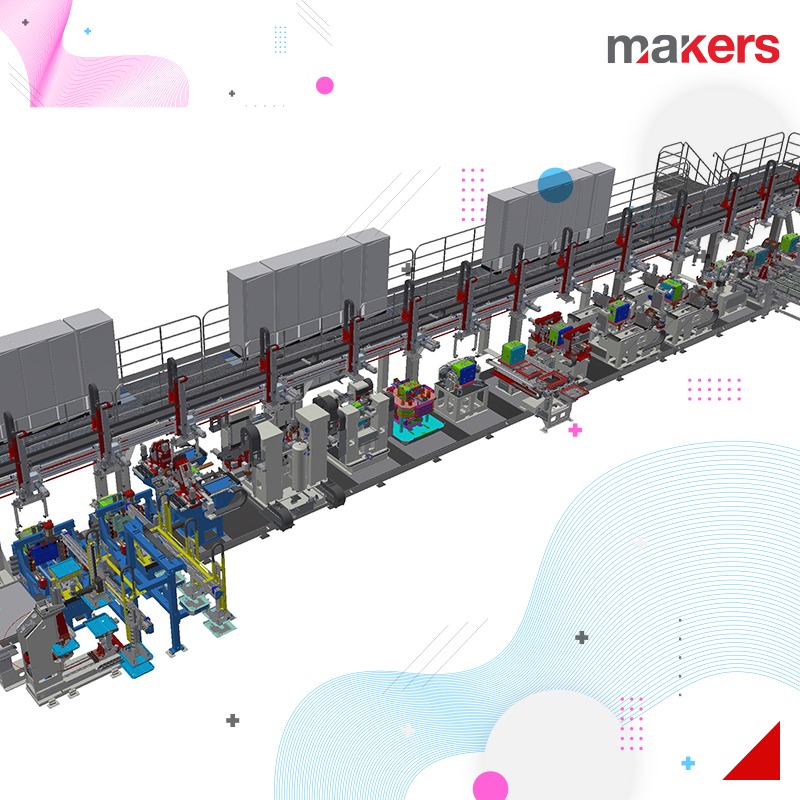

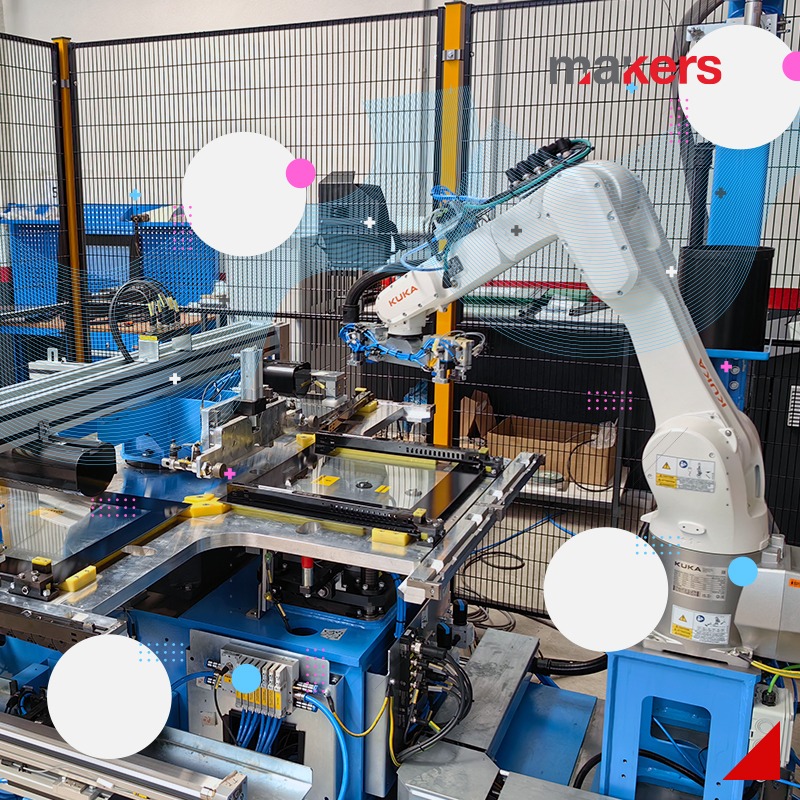

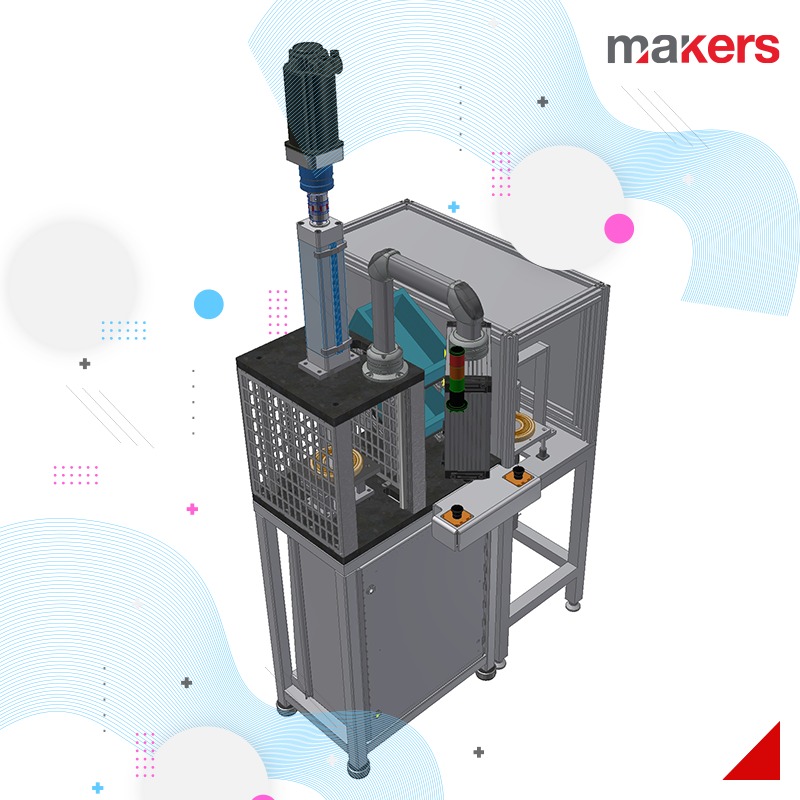

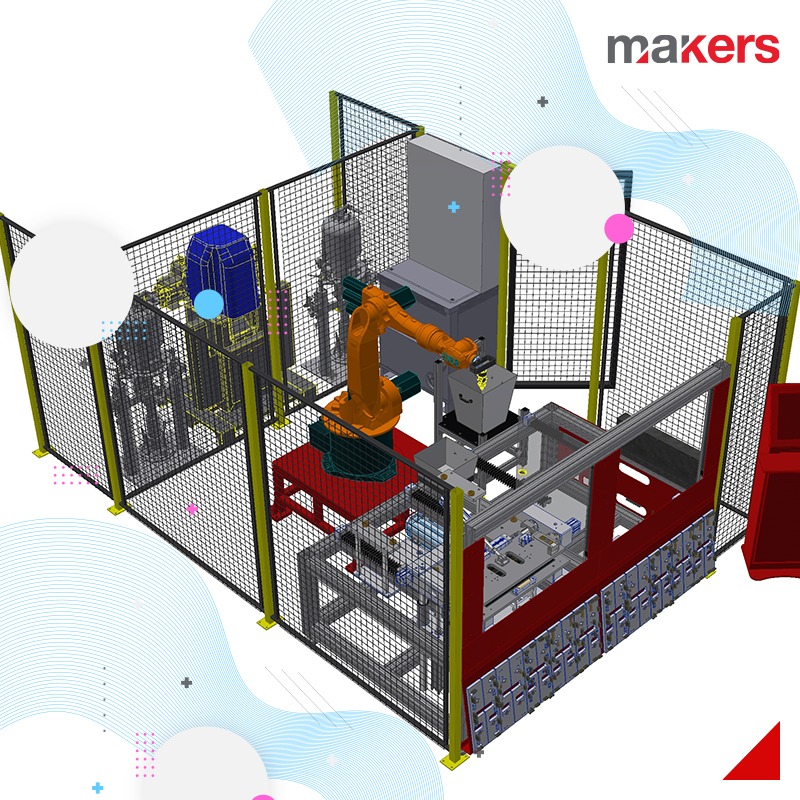

In glass loading, glass unloading and glass transfer processes; we install the lines using Cartesian robots, 4-axis and 6-axis robotic applications. We carry out the glass treatment process on drilling machines that we manufactured and designed ourselves. We also aim to take part in the glass screen printing machine sector.

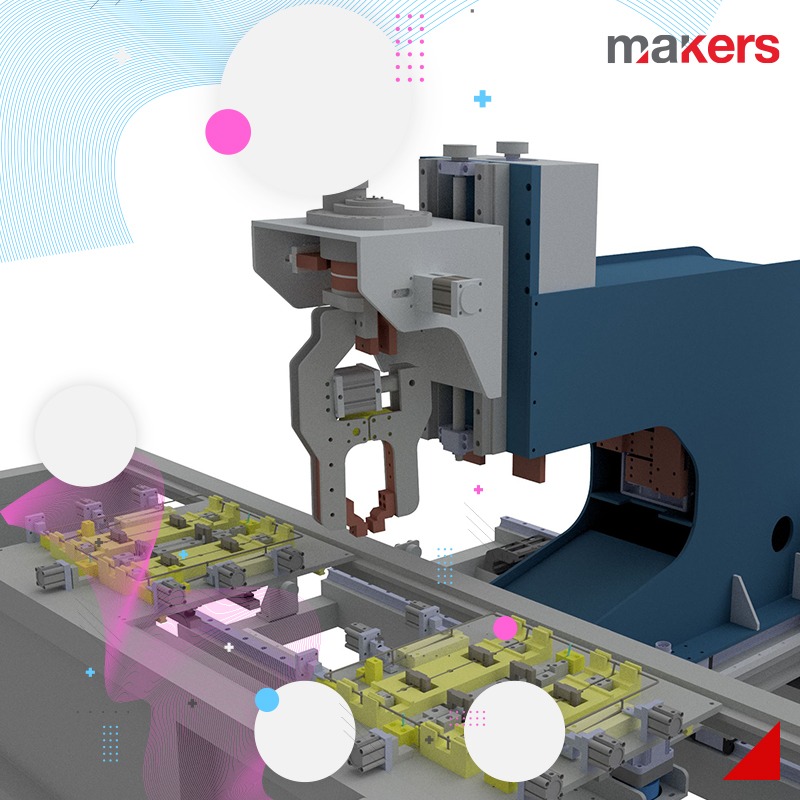

Glass Transfer Cartesian System: In the glass industry, visuality and quality are very important and the glass used especially in the white goods industry is also heavy. These related glasses are usually cut into certain lengths, stacked and transported by pallets and fed to conveyors to be shaped or processed. In order to prevent any damage to the glass during this feeding process and/or because of the difficult handling of heavy glass by the operator, the system that can do this job best is the Cartesian system, which can be 3-axis or 2-axis depending on the application. These systems hold the glass on the pallet with the help of a pneumatic vacuum and gently release it onto the conveyor, thus preventing scratches and/or operator strain due to weight.

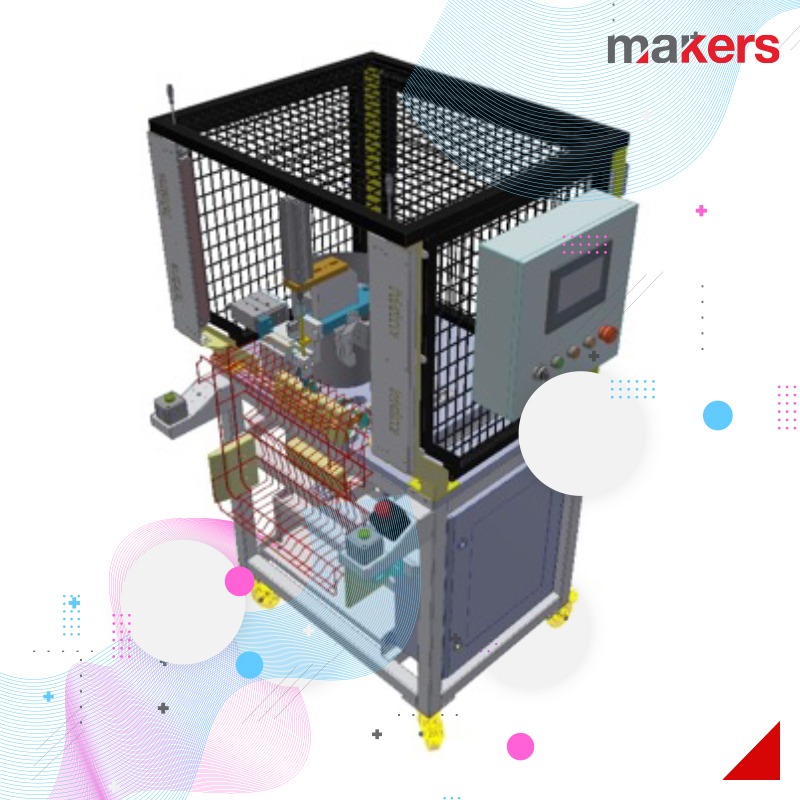

Silk Screen Printing: Makers develops its expertise in drilling and transfer systems in the glass industry with the production of machines for screen printing on glass. Design, production, automation and commissioning processes can also be carried out in accordance with the required flat glass screen printing machines, glass sizes requested. Heating and cooling ovens can also be included in the system and the entire process can be created. Different prints are possible sequentially with 2 and 3-screen printing lines. In all processes, there are also miter systems according to glass sizes.