Two Component Bonding Machine for

Oven Door Applications

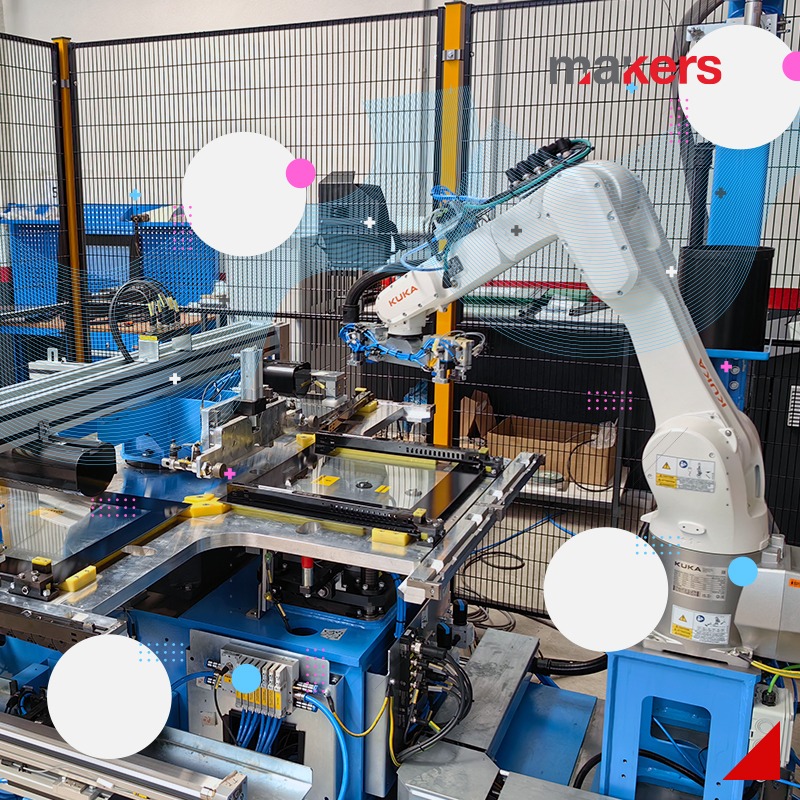

This line is working as a semi-automatic for surface cleaning, bonding and assembly application.

The system consists of a 4-station turntable station, a silicone dosing unit, a plasma surface cleaning unit and a 6-axis robot. Loading and unloading processes will be done manually by the operator. 1 operator will be enough for this process.

At the 1st station, the products are fed to the line manually by the operator. Surface cleaning is performed by performing plasma treatment at the 2nd station, the module will be pneumatically driven. The product that has been cleaned is taken to the siliconization unit and the siliconization process is done from the top with the help of a robot. Bonding and curing process will take place at the 4th station.

The finished product comes in front of the operator and the operator takes the finished product from the machine manually. It continues its process by replacing it with new products.