Factory Automation

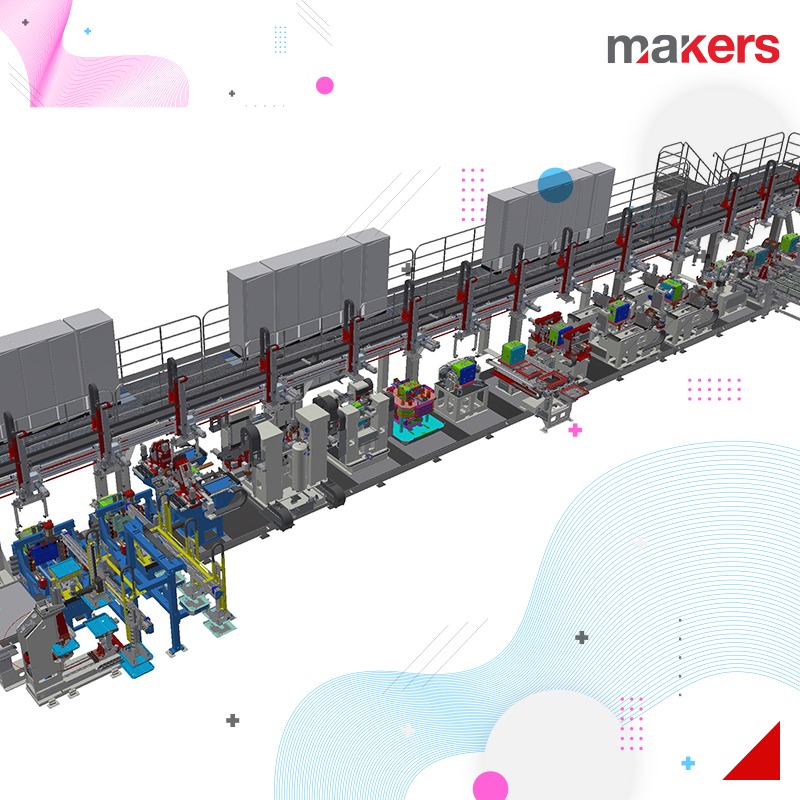

BondingLines

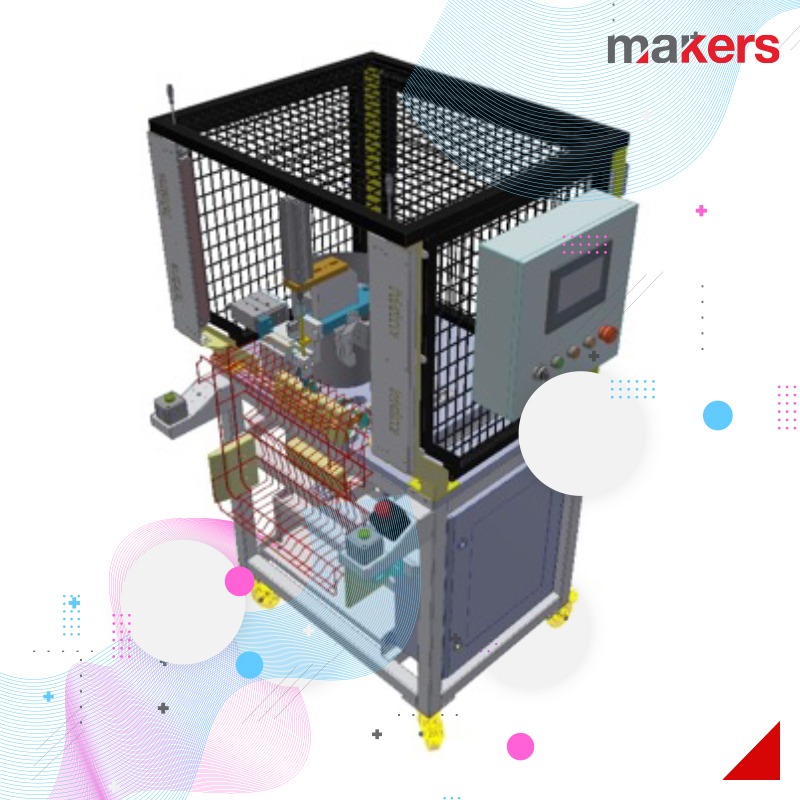

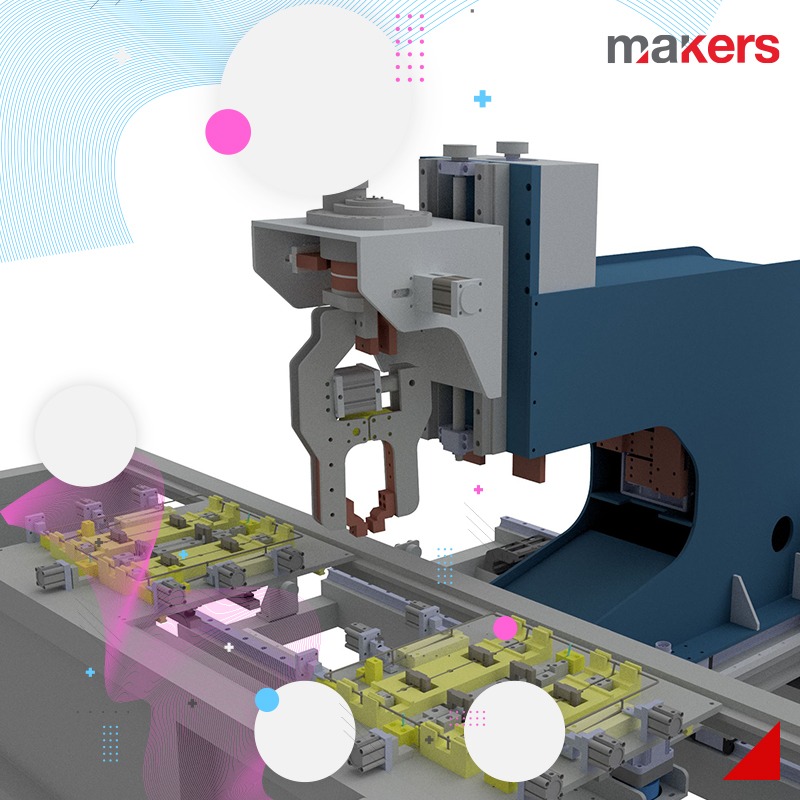

Bonding lines are automation applications where error tolerance ranges are very low. The process, which starts with holding the material to be bonded in the appropriate positions, is based on the precise application of single or double component adhesives with different technical properties to the relevant surfaces.

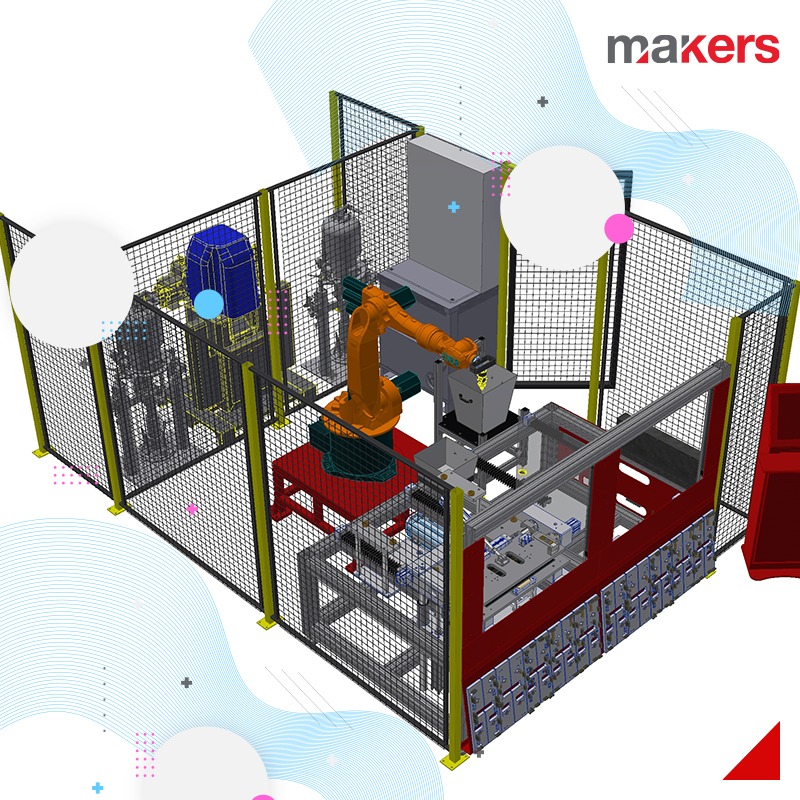

We establish bonding lines with our "innovative engineering" approach with special sealants, adhesives or process-specific materials for the needs of all sectors, especially the white goods sector.

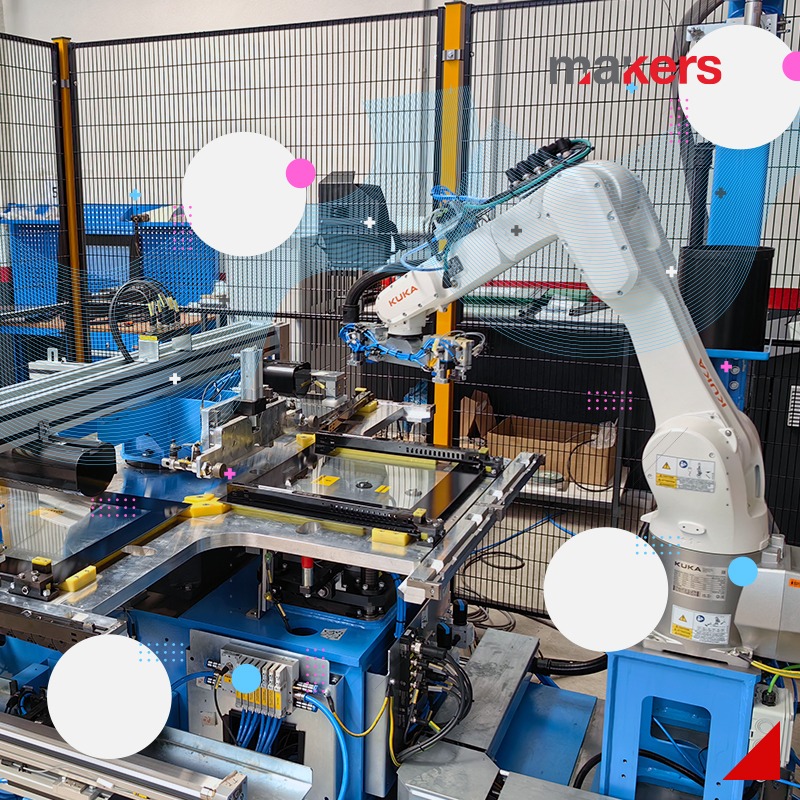

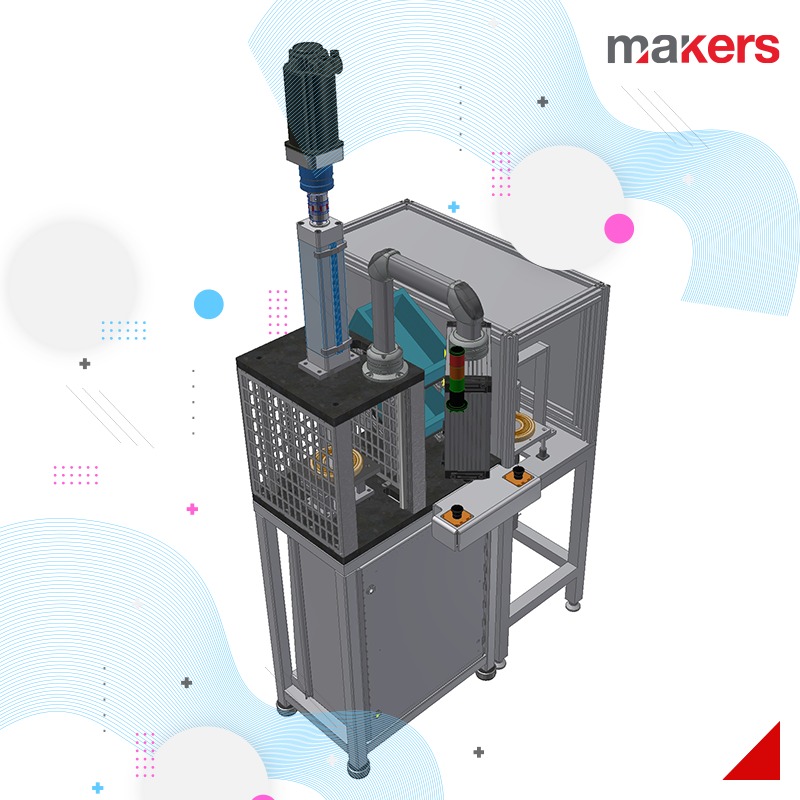

Before the bonding processes in combinations such as Glass-Plastic, Plastic-Sheet Metal, Metal-Glass, we clean the surface of the material with applications using plasma technology and increase the bonding efficiency. In the continuation of the track, we end the bonding process by automatically applying the appropriate bonding chemical to the relevant surfaces or sections with 6-axis or Cartesian robot methods.

In line with the requests of our solution partners, we can also add surface treatment options such as curing buffer to the track.