Top Table

Bonding Process

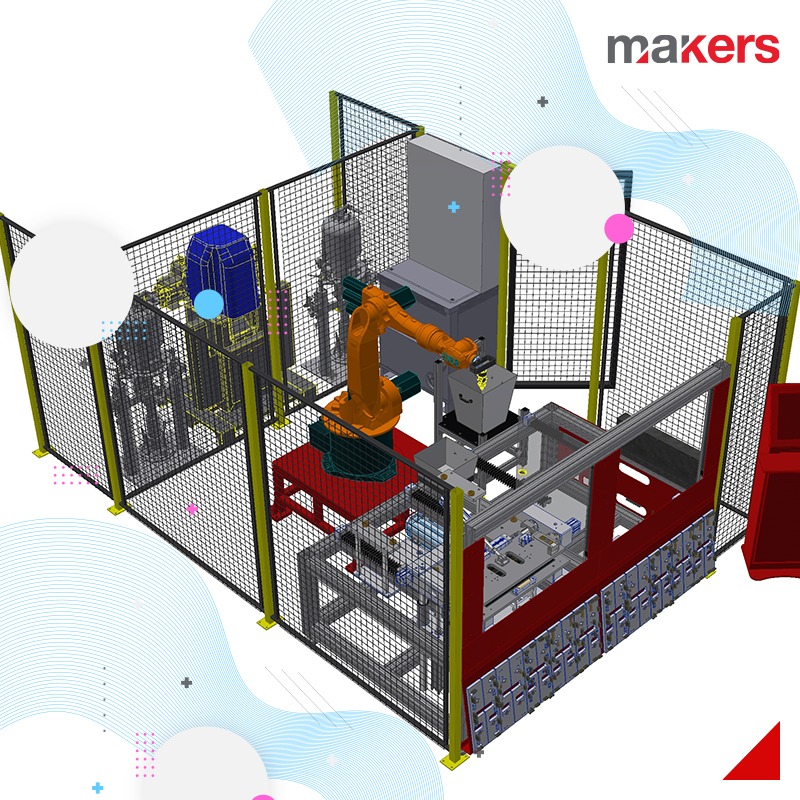

It is a project realized, by MAKERS, in the process of joining chipboard and plastic frame during the production of top tables of washing machines, dishwashers and dryers in the white goods sector.

Due to the high production quantities in the white goods sector, two-component systems are generally used in bonding processes. In applications made with a mixture of two chemical materials, the stacking time of the products is minimized. The curing time of the two-component material we used in the top table bonding project is less than 30 seconds. A product can be obtained from the line in 20 seconds.