Factory Automation

Assembly Lines

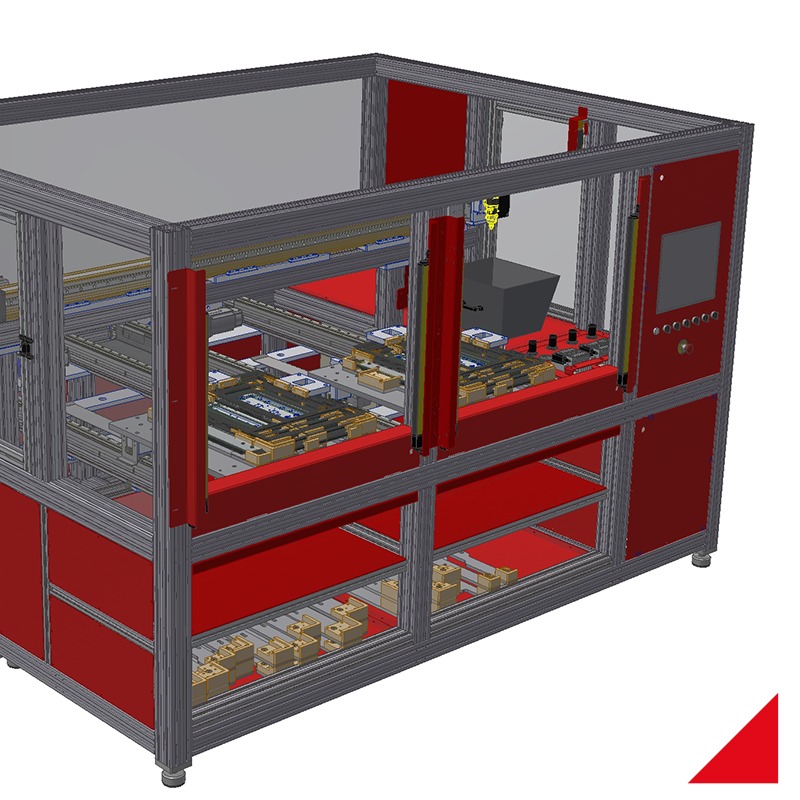

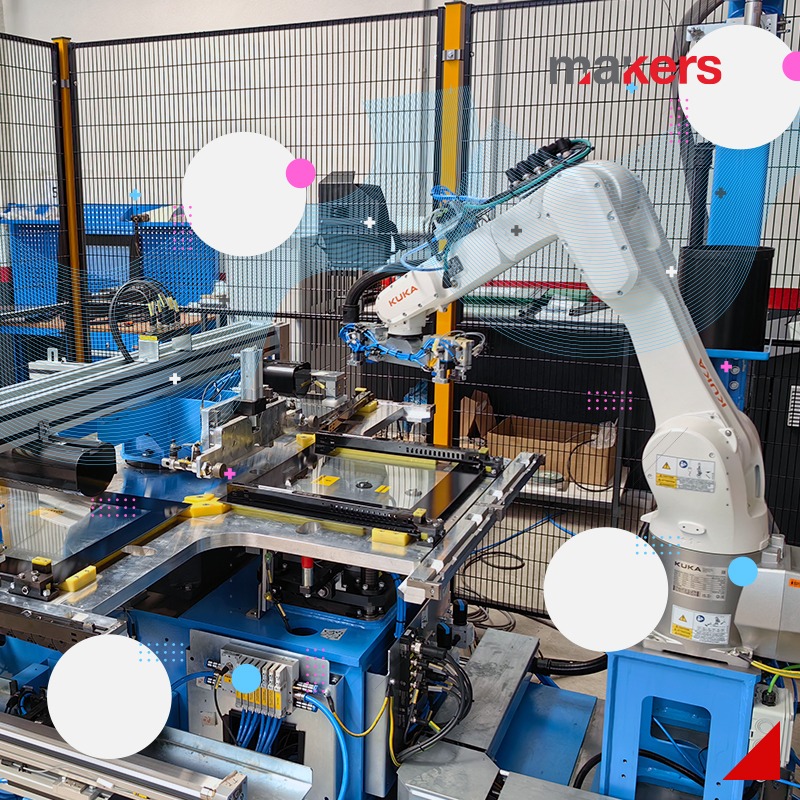

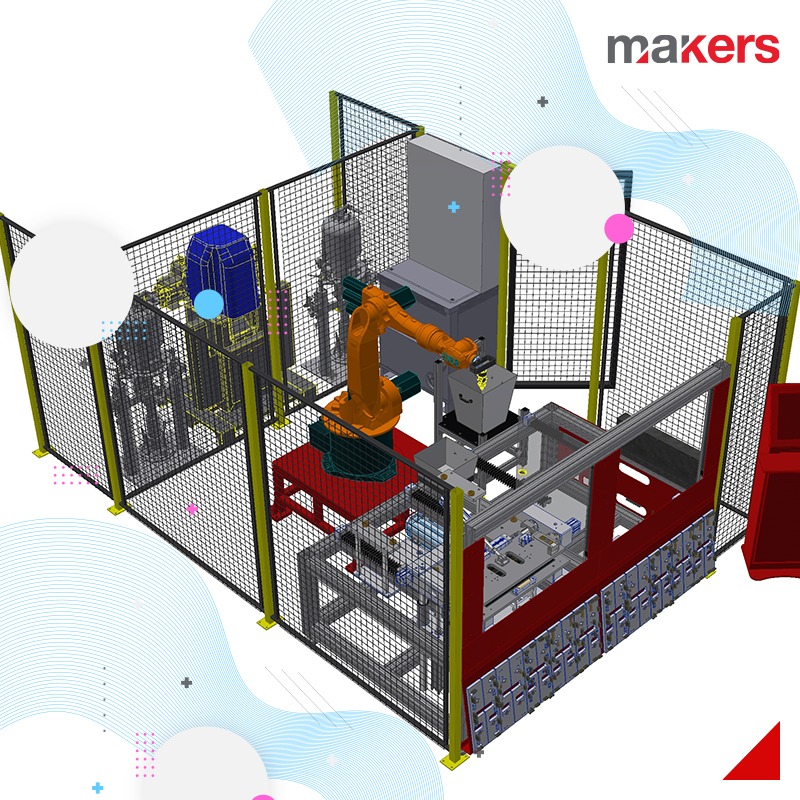

We produce modular automatic assembly lines for factory automation where all positions and movements can be changed with a single command. While realizing the projects, we work with our "innovative engineering" approach at all stages starting from design to commissioning.

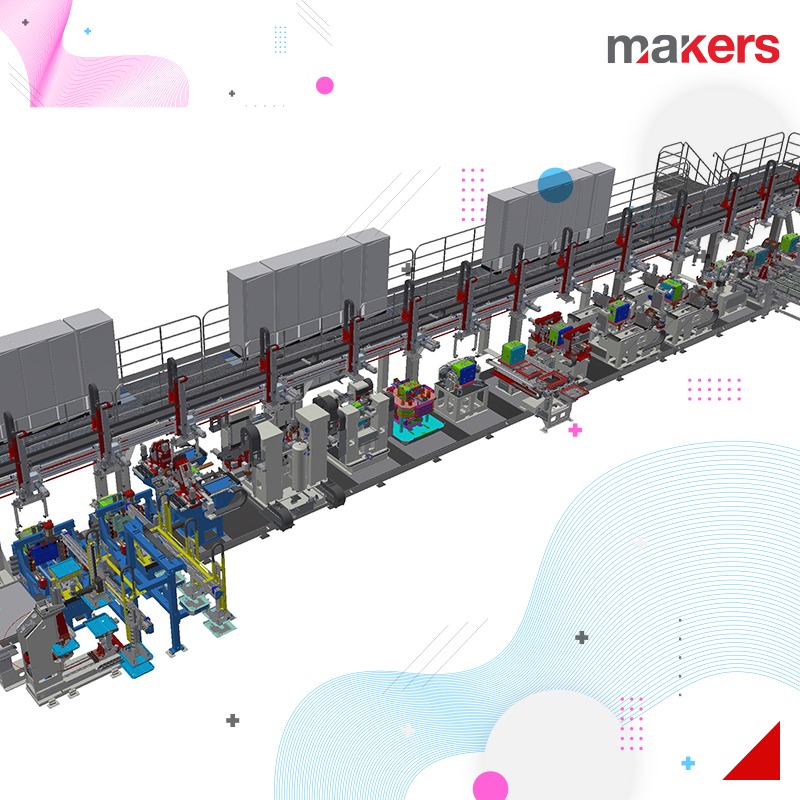

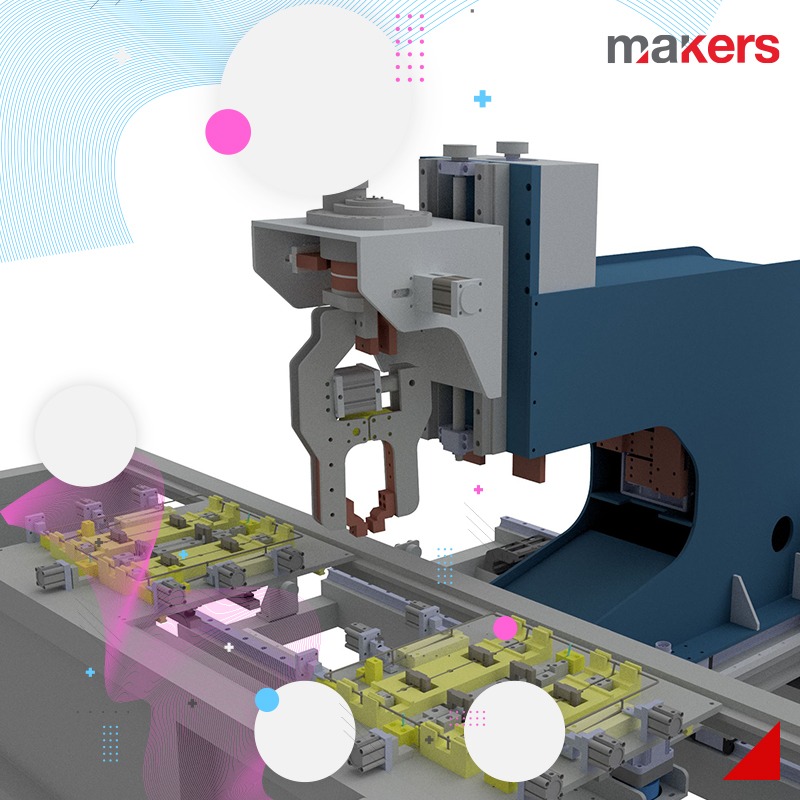

We realize assembly line applications with unique processes that we design depending on the material and physical properties of the product or product groups to be assembled.

In order to achieve maximum robustness with minimum movement, time and consumption, we simulate the assembly processes in a digital environment, detail the processes and set up the track.

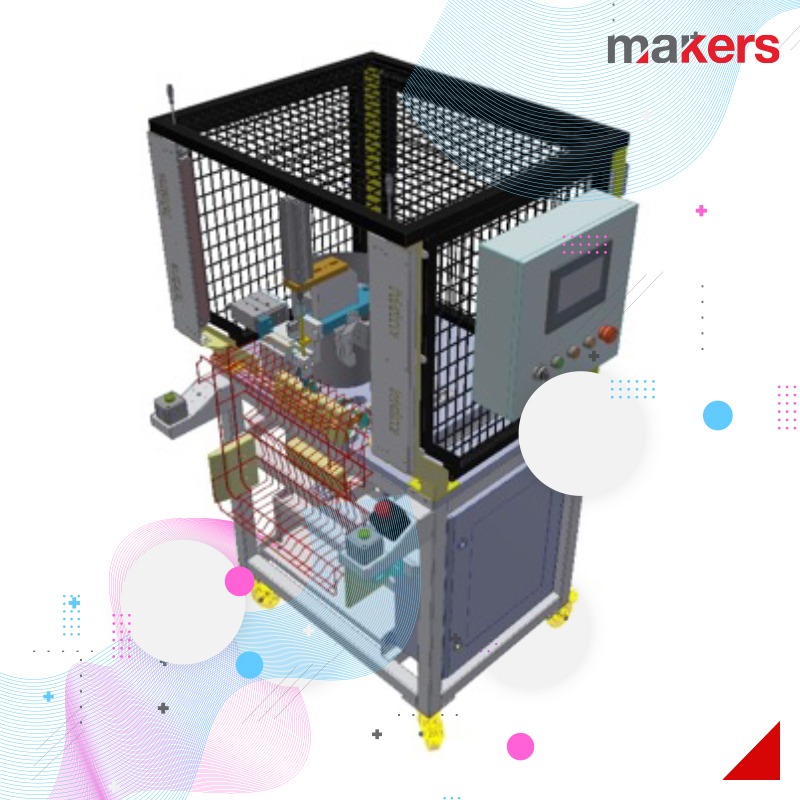

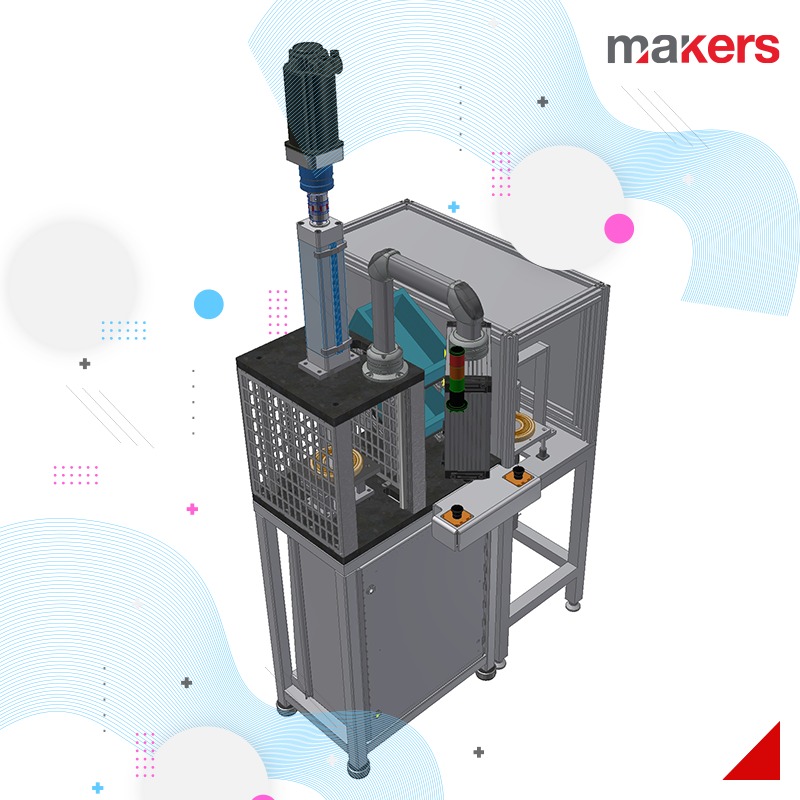

In factory automation assembly line applications; we provide solutions by making them unique to the product and process with rotary table options, automatic or semi-automatic system solutions, single line alternatives.