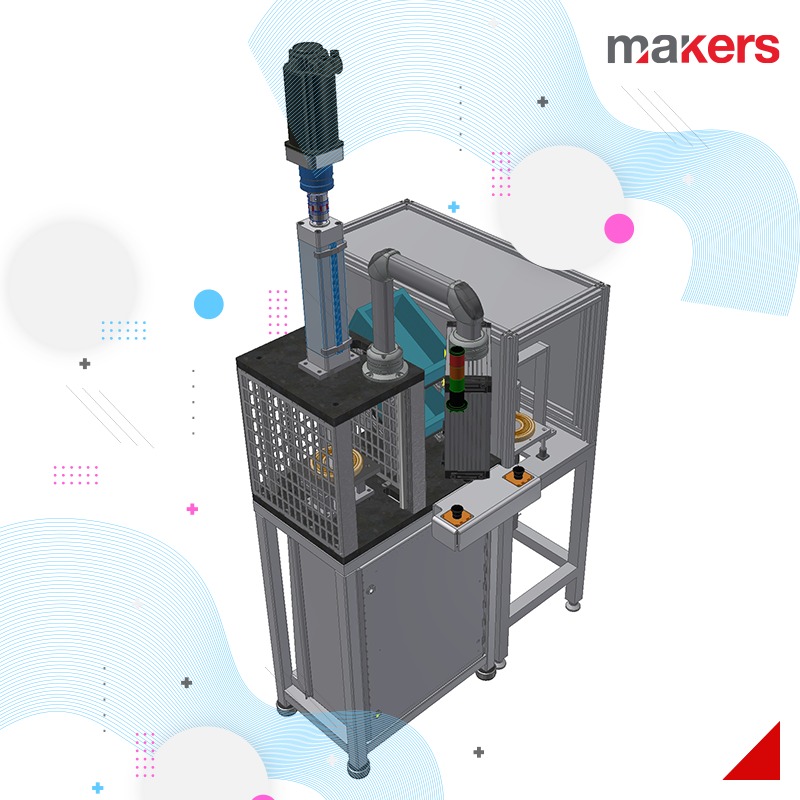

Servo Press

Manufactured for Automotive Industry

The press in question, manufactured by Makers, is a press machine that uses a servo motor as the drive source. The advantage of a servo motor is that it can control both the position and speed of the output shaft compared to a constant rotational speed. With a load capacity of up to 10 tons, it is a high-precision application that can provide torque, speed and position control according to the needs.

Servo presses are more advantageous applications than mechanical presses.

The Servo Press has an adjustable stroke; the required press load can be set for sliding motion, deep drawing stamps, then different programming can be done to allow for shallow part stamps and even blanks.

Compared to a standard mechanical press, Servo Presses have up to 37% higher cycle rates.

Energy Savings: The Servo Press does not have a flywheel running continuously, which reduces energy consumption costs.

Quality:

Better forming stability means less part rejection.

Longer tool life:

Reducing the tool impact speed while simultaneously shortening the cycle time reduces the impact load and thus maximizes tool life. Increased lubrication efficiency has been observed and the use of vibratory or oscillating sliding motion can further extend tool life.

Run Time:

Synchronized clutching and extended brake life results in less frequent maintenance and improved equipment uptime.