Makers, with its strong team with experience in factory automation, carries out all processes from project design to delivery with the same quality level. All production takes place in the production machine parks in Makers’s plant.

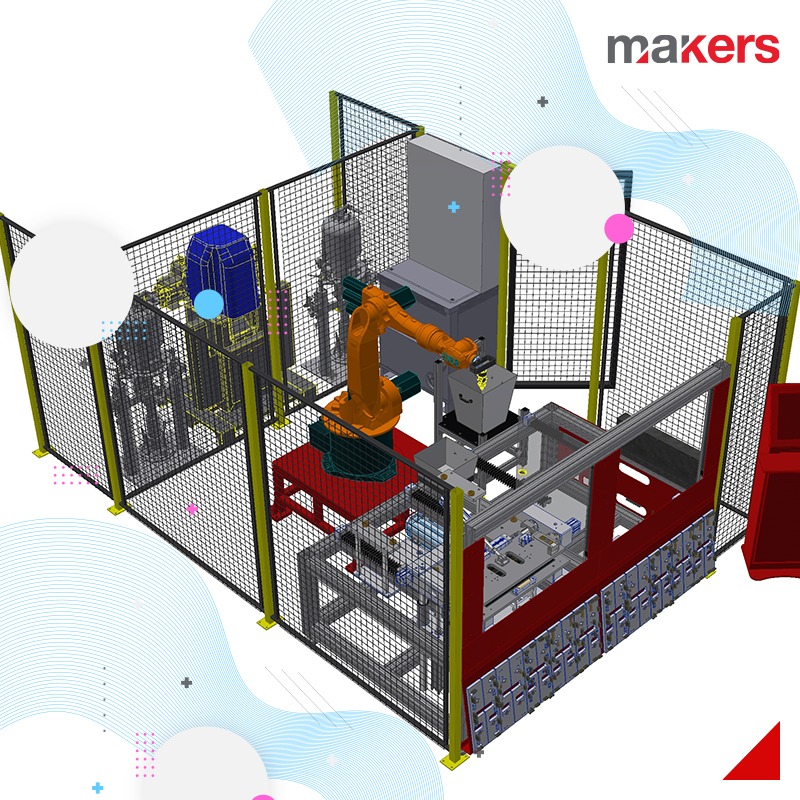

Makers use 6 axis or cartesian robot technologies according to the needs of the customers’s project in machine or assembly line. We design and optimize application systems with simulation applications before manufacturing with our robotics team, who are especially competent in handling, palletizing, part feeding and gluing applications.

Makers aim to make machine manufacturing solutions compatible industry 4.0 for the demands of our solution partners in welding automation, transfer systems, bonding automation and assembly lines with our experience in home appliance, automotive, glass and general industry.

Makers is a new and fast-growing group company established under the leadership of the core team of HKTM, which has the ability to do business in Turkey and all over the world and has the sectoral experience, and has been organized with the aim of signing major automation projects worldwide, focusing especially in the field of white goods factory automation.

Working with up-to-date technology facilities, talented human resources, and corporate business policies and principles, Makers produces innovative engineering solutions to bring them together with the industry in conditions that will be efficient and profitable for everyone.

Makers

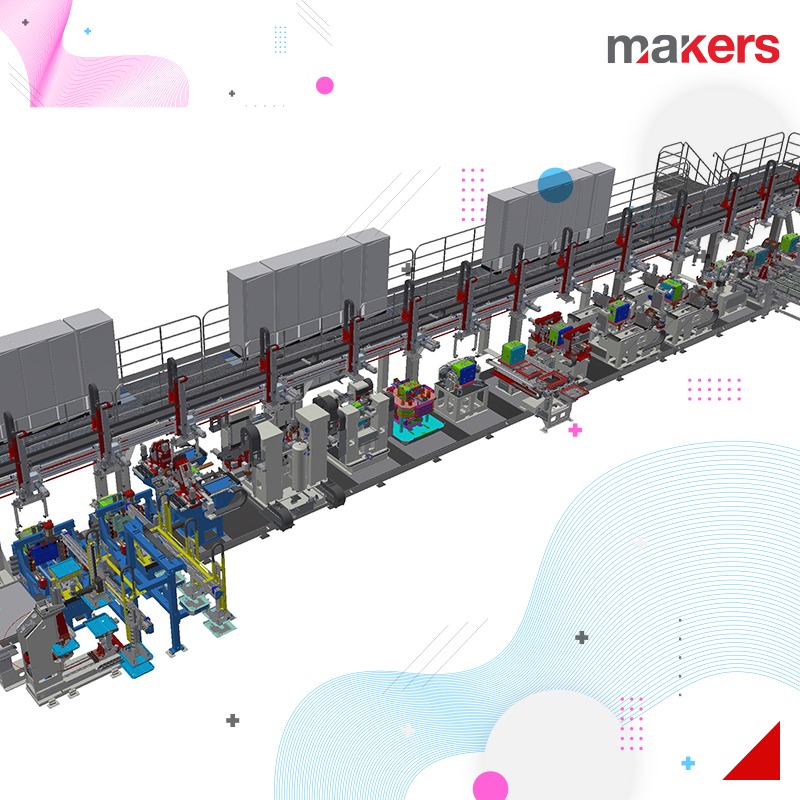

A production line consisting of 16 different machines, 20 Cartesian, 3 hydraulic presses, more than 15,000 I/O, 7 robots, 88 servo motors, 3,500 pages of electrical projects and countless electrical components.

More

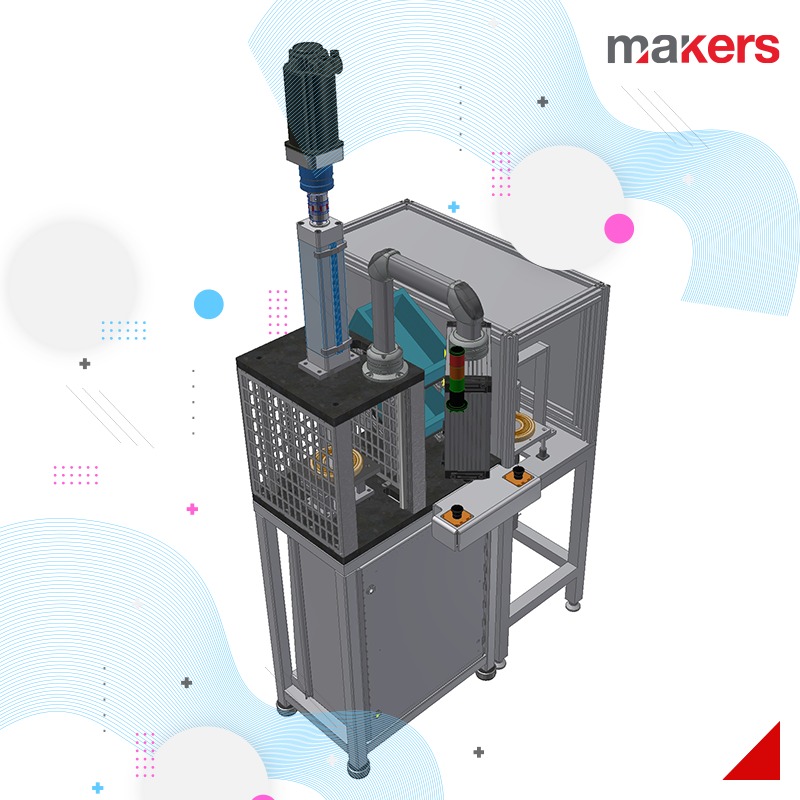

It is a machine that drills holes on flat glass at high precision coordinates determined for use in the white goods industry. Depending on the process, it drills 4 or 2 serial holes on the flat glass material flowing on the serial ...

More

The press in question, manufactured by Makers, is a press machine that uses a servo motor as the drive source. The advantage of a servo motor is that it can control both the position and speed of the output...

More

In this project, in which we are a solution partner with the White Goods company, we are proud of creating a beautiful work as a result of coordinated work with both our hydraulic and mechanical...

More

As HKTM, we delivered 2 sets of this machine to the leading auxiliary industry company of the white goods sector in Turkey, where we maintained our activity in the previous years, and...

More

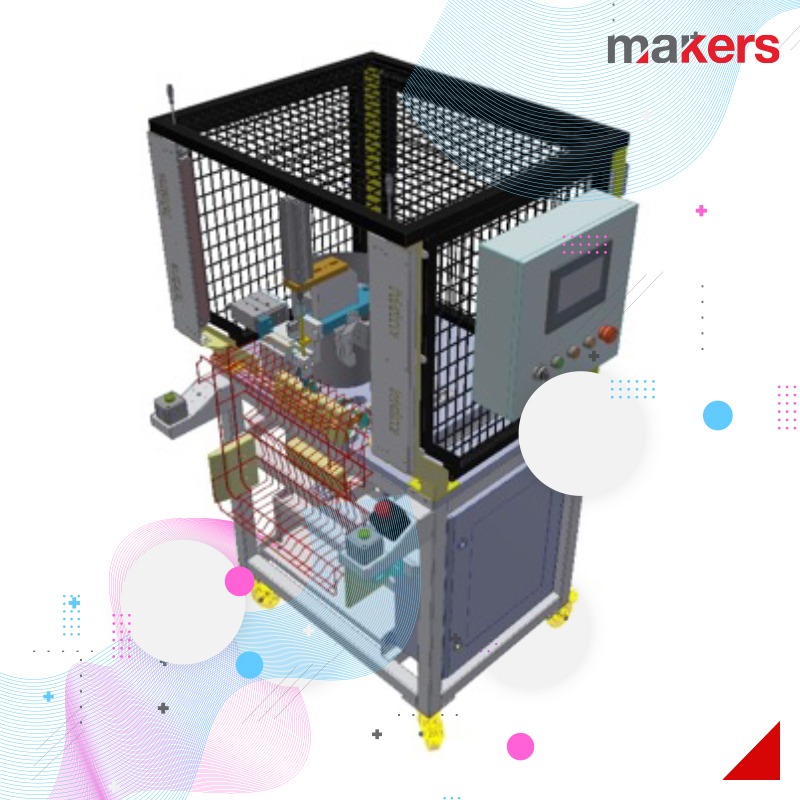

The machine joins two existing parts with a "Desoutter" screwdriver. There are pneumatic cylinders for locking the product and making screwdriver movements. There is also a vacuum system to remove sawdust.

More

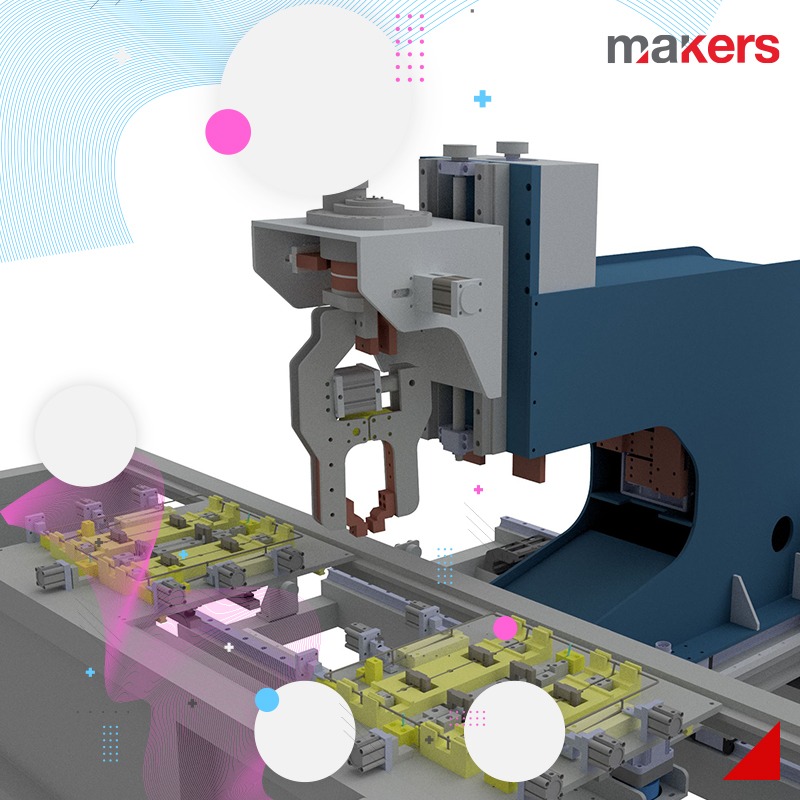

It is a project realized, by MAKERS, in the process of joining chipboard and plastic frame during the production of top tables of washing machines, dishwashers and dryers in the white goods sector.

More

It is an assembly line with an automation system that assembles the expansion tanks of the boilers in progressive and serial flow processes by keeping sustainable quality control at the forefront and...

more